Do you want to revolutionize and streamline your business operations? Supply chain integration might be the solution you’re looking for. Integrating all sectors of the supply chain, from planning, procurement, and production to distribution and after-sales service, allows for better communication between departments and suppliers to understand better and meet customer needs. DFreight, a digital freight forwarder, With its online platform and mobile app, revolutionizes business operations by integrating many supply chain sectors.

Read on to discover how supply chain integration can help revolutionize your business today!

Table of Contents

What is Supply Chain Integration?

Supply chain integration is the connection of processes and information across a company’s supply chain, which includes vendors, manufacturers, distribution centers, and customers. This integration allows organizations to better collaborate in managing the product life cycle, from source to delivery. It also enables companies to identify and address any potential issues that may arise throughout the supply chain. It leads to higher customer satisfaction and cost savings, allowing businesses to realize greater success.

How Supply Chain Integration Can Help Revolutionize Business Operations

Supply chain integration can help revolutionize business operations by enabling companies to respond quickly to customer demand and increase efficiency. It also helps companies better manage inventory levels and reduce the cost of shipping. Furthermore, it can improve customer service by providing timely information and helping streamline ordering and distribution processes. Improved customer service leads to increased sales and growth.

Additionally, supply chain integration can help companies reduce their environmental footprint. Companies can reduce their energy consumption and costs by establishing more efficient supply chain practices. It also enables companies to save additional money by avoiding waste and improving their efficiency in the use of resources.

Overall, supply chain integration allows companies to make well-informed decisions about their supply chain that may benefit their customers, staff, and the environment. It provides companies the tools and information they need to achieve their goals and drive growth. By leveraging the power of supply chain integration, businesses can revolutionize their processes and create a more efficient and successful operation.

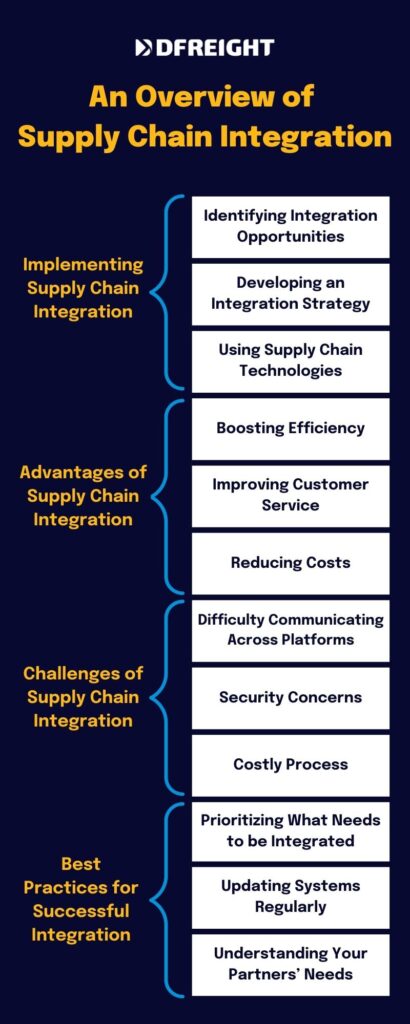

Implementing Supply Chain Integration

Identifying integration opportunities is the first step to implementing supply chain integration. This includes finding areas that could be faster, more efficient, and easier to coordinate. After identifying the areas of improvement, businesses must create an integration strategy to implement the changes. This includes determining the specific technologies and support required to ensure a successful transition.

Advantages of Supply Chain Integration

One of the primary advantages of supply chain integration is boosted efficiency. Integrated supply chains allow for faster order fulfillment and better customer service, as different partners in the supply chain are informed and updated as soon as any changes occur. Lower costs are also a significant benefit of that, as businesses can reduce redundancy and inefficiencies in the process.

Challenges of Supply Chain Integration

Challenges arise when different systems are being used to integrate the supply chain. Communication can be difficult when different technologies are being used and there are compatibility issues. Additionally, security concerns are paramount, as data must be securely stored or transmitted from partner to partner to keep customer information safe.

Best Practices for Successful Integration

When attempting to implement supply chain integration, businesses must prioritize which activities need to be integrated first. They should also strive to update and upgrade their systems regularly to ensure they get the most up-to-date technology. It’s also essential to understand the needs of each partner, as different partners may require different methods or processes for best results.

Available Technologies for Supply Chain Integration

Integrating supply chain technologies today is essential for businesses to drive higher efficiency, streamline operations, and improve decision-making processes. The following are some of the available technologies that can be used to integrate the supply chain:

Blockchain: Blockchain technology can be used to improve supply chain transparency and traceability and enable secure transactions. It offers a secure and distributed decentralized ledger that makes transactions safer by preventing counterfeiting.

Internet of Things (IoT): IoT is a network of connected ‘things’ that can collect and send data back to a central processing point. It helps to automate and improve supply chain processes by providing real-time granular data that can be used to detect errors, track shipments, and automate forecasting and inventory management.

Artificial Intelligence (AI): AI-enabled systems can automate processes like order fulfillment, route selection, and demand forecasting and can provide valuable insights into customer preferences. AI also enables predictive analytics that can be used to anticipate customer needs and make smarter decisions.

Cloud Computing: Cloud computing combined with other technologies can help to simplify supply chain management and help companies to make decisions faster. Cloud solutions enable the sharing of data in real time and help improve communication and collaboration among different partners in the supply chain.

Advanced Planning and Scheduling (APS): APS uses algorithms to optimize the time, personnel, and resources available for planning and scheduling tasks. It offers enterprises faster and more accurate planning, enabling them to respond quickly to changes and address unexpected situations.

Enterprise Resource Planning (ERP): ERP is an integrated IT platform that helps companies manage their core business processes like finance, HR, production, and inventory.

Warehouse Management Systems (WMS): WMS offer tools to manage the storage, pick-up and delivery of products.

Customer Relationship Management (CRM): CRM systems are used to organize, record, and manage customer information.

Transportation Management Systems (TMS): TMS are designed to optimize the transportation of goods and reduce associated costs.

Supplier Management Systems (SMS): SMS are used to automate communications with suppliers, helping to streamline the procurement process.

The technologies discussed above offer great potential for improving supply chain efficiency, but businesses must carefully consider the pros and cons before investing in these technologies. To ensure successful implementation, aligning the technology with the company’s current processes and developing a well-defined strategy is essential.

Conclusion

Supply chain integration is a great way for businesses to take advantage of various technologies and achieve greater success. Through direct communication and efficient coordination, businesses can see improvements in customer service, cost savings, and overall efficiency. With the proper implementation strategy and the best practices for success, businesses can maximize the benefits of supply chain integration and revolutionize their operations.

What is supply chain integration?

Supply chain integration is a process that integrates different supply chain activities, such as inventory management, logistics planning, and production. Companies use supply chain integration to ensure consistency and accuracy in the supply chain process.

What benefits does supply chain integration offer?

Supply chain integration offers advantages such as improved efficiency, lower operational costs, better customer service, more accurate data, and increased visibility into business operations.

What technology is used for supply chain integration?

Supply chain integration uses cloud-based technologies, artificial intelligence (AI), blockchain, and other automation solutions to improve business operations.

How does supply chain integration reduce costs?

Supply chain integration streamlines processes and eliminates manual steps in the supply chain, reducing labor costs and increasing operational efficiency, leading to further cost savings.

What is an example of a supply chain integration solution?

An example of a supply chain integration solution is an enterprise resource planning (ERP) system, which provides a unified platform for tracking orders, approving shipments, and managing inventory.

Is it possible to integrate supply chain systems from different vendors?

Yes, it is possible to integrate supply chain systems from different vendors. This requires careful planning and implementation of strategies to ensure compatibility between systems.