Intel Corporation is one of the world’s leading tech companies, and its supply chain strategy is integral to its success. In this blog post, you’ll gain an insight into Intel’s supply chain strategy and understand why it has succeeded. From managing supplier relationships to optimizing its inventory, Intel has a well-defined strategy that has kept it ahead of the competition. Read on to discover how Intel has used its supply chain to gain a competitive edge and how it continues to innovate and evolve.

Table of Contents

Overview of Intel’s Supply Chain

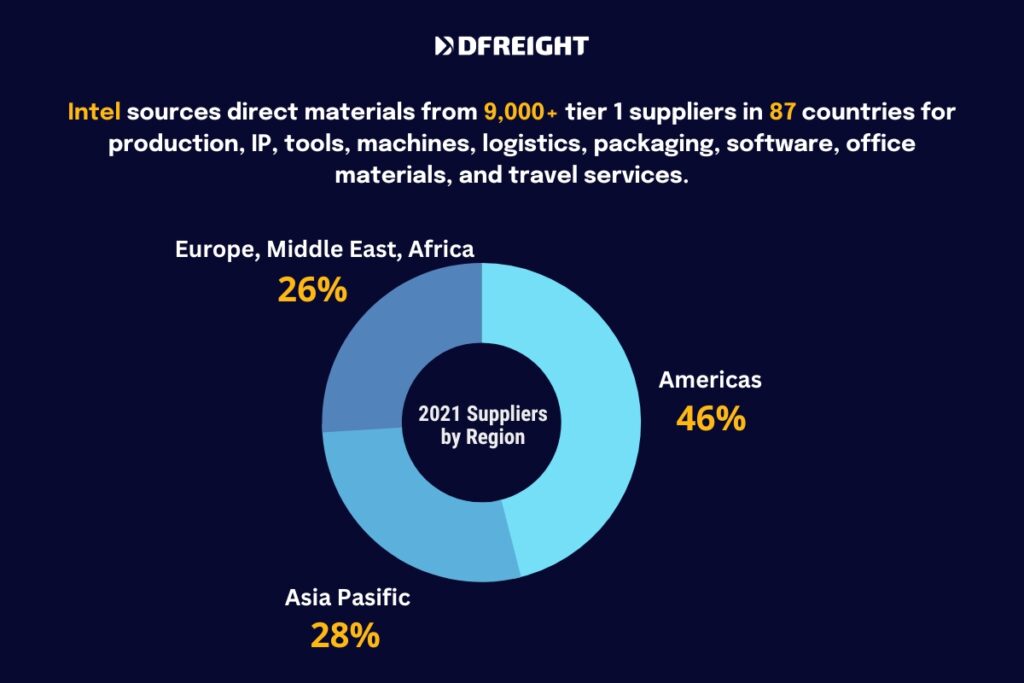

Intel is one of the world’s largest semiconductor companies and a significant player in the global technology market. As a result, the company’s supply chain is complex and highly efficient, relying on international partnerships, advanced planning and optimization, automation and technology, and quality control and risk management.

Intel’s supply chain is divided into two main components:

- Manufacturing supply chain: The manufacturing supply chain produces Intel’s microprocessors, motherboards, and other components.

- Product supply chain: The product supply chain is responsible for distributing these products to customers.

Intel’s supply chain is divided into four layers:

- Suppliers: At the supplier level, Intel has developed a network of global partnerships to ensure it has access to the best components at the most competitive prices. The company also works closely with its suppliers to ensure that components are delivered on time and meet quality standards.

- Manufacturing: At the manufacturing level, Intel’s supply chain relies heavily on advanced planning and optimization. The company’s supply chain professionals use sophisticated software systems to track production schedules, inventory levels, and customer requirements. This allows Intel to ensure that its production is aligned with customer needs and that materials are available for production when needed.

- Distribution: At the distribution level, Intel utilizes automation and technology to streamline the shipping and delivery of its products. The company’s warehouses are highly automated, with RFID and barcode scanners tracking shipments and inventory levels. This allows Intel to quickly and accurately deliver its products to customers.

- Customers: Finally, at the customer level, Intel employs quality control and risk management processes to ensure the quality of its products and reduce potential risks. The company’s quality assurance team regularly inspects products at all supply chain stages to ensure that they meet Intel’s stringent standards. In addition, Intel employs risk management strategies to minimize the impact of possible disruptions in the supply chain.

In the previous blogs, we looked into the supply chains of famous and leading companies, which you can read about each of them in the section below.

| Apple | Samsung | Walmart |

| Schneider Electric | Tesla | BMW |

| Adidas | Nike | H&M |

| Amazon | IKEA | L’Oréal |

| McDonald | Coca-Cola | Zara |

| Starbucks | Pepsi | Honda |

| Toyota | Unilever | Costco |

| Nestle | ADNOC | KFC |

Intel Supply Chain Strategy

Intel has developed a comprehensive supply chain strategy to deliver quality products to its customers efficiently and cost-effectively. The company’s approach focuses on four key areas: globalization, advanced planning and optimization, automation and technology, and quality control and risk management.

Globalization

Intel has built a global network of suppliers to ensure access to the best components at competitive prices. The company works closely with its suppliers to ensure that components are delivered on time and meet quality standards. This allows Intel to reduce costs and maximize its profits.

Advanced Planning and Optimization

Intel uses advanced planning and optimization software systems to track production schedules, inventory levels, and customer requirements. This allows Intel to ensure that its production is aligned with customer needs and that materials are available for production when needed. The company also uses analytics to identify potential bottlenecks and process improvements in its supply chain.

Automation and Technology

Intel utilizes automation and technology to streamline the shipping and delivery of its products. The company’s warehouses are highly automated, with RFID and barcode scanners tracking shipments and inventory levels. This allows Intel to quickly and accurately deliver its products to customers. The company also uses predictive analytics to anticipate customer needs and optimize its supply chain operations.

Quality Control and Risk Management

Intel employs a rigorous quality control process to ensure its products meet the highest standards. The company’s quality assurance team regularly inspects products at all supply chain stages to ensure that they meet Intel’s stringent standards. In addition, Intel employs risk management strategies to minimize the impact of possible disruptions in the supply chain.

Intel Supply Chain Challenges

Intel’s supply chain is complex and efficient, but it is not without its challenges. The company must manage a global network of suppliers, coordinate production schedules, and ensure that its products meet the highest quality standards.

In addition, Intel must respond quickly to changes in customer demand, as the company operates in a highly competitive market. The company must also manage the risk of potential disruptions in the supply chain, such as natural disasters or political instability, which can significantly impact its operations.

Intel must continually innovate to ensure its supply chain remains competitive. This includes using new technologies, such as automation and predictive analytics, to improve efficiency and reduce costs.

Environmental Impact

Environmental impact is a principal supply chain challenge at Intel!

Environmental impact is one of the major supply chain challenges faced by Intel. As a leading producer of computer chips and other electronic devices, Intel has a responsibility to mitigate the environmental impact of its supply chain. Intel is committed to reducing its carbon footprint and using renewable energy sources. To meet this goal, Intel has implemented a number of initiatives, including reducing energy consumption, using recycled materials, and improving recycling processes.

Intel has also adopted the United Nations’ Global Compact, which encourages responsible practices in the electronics industry. Overall, Intel is committed to minimizing the environmental impact of its supply chain and ensuring that its operations are sustainable.

According to Intel’s 2030 RISE Strategy and Goals, operational and supply chain goals to protect the environment are as follows:

- 100% Green Power: Achieve 100% renewable electricity use across

our global manufacturing operations. - Energy Conservation. Conserve 4 billion kWh of energy.

- Emissions Reductions. Drive a 10% reduction in our absolute Scope 1

and 2 GHG emissions as we grow, informed by climate science. - Product Energy Efficiency. Increase product energy efficiency

10x for Intel client and server microprocessors to reduce our

Scope 3 emissions. - Net Positive Water. Achieve net positive water—by conserving 60

billion gallons of water and funding external water restoration projects. - Zero Waste to Landfill. Achieve zero waste to landfill and implement

circular economy strategies for 60% of our manufacturing waste

streams in partnership with our suppliers.

Intel Supply Chain Benefits

Intel’s supply chain strategy has enabled the company to remain competitive in the global technology market. The company’s global network of suppliers ensures it can access the best components at competitive prices. Advanced planning and optimization allow Intel to ensure that its production is aligned with customer needs and that materials are available for production when needed. Automation and technology streamline the shipping and delivery of products, while quality control and risk management processes ensure that Intel’s products meet the highest standards.

Unlock the Power of Digital Freight Forwarding

Take the hassle out of freight forwarding with DFreight! DFreight is a digital freight forwarder that offers an online platform and mobile app to streamline your supply chain strategy. Get instant pricing, book shipments, and track your goods in real time with 24/7 visibility. Join us today and see the difference DFreight can make for your business!

What is Intel’s supply chain strategy?

Intel’s supply chain strategy focuses on four key areas: globalization, advanced planning and optimization, automation and technology, and quality control and risk management.

What is Intel’s supply chain?

Intel’s supply chain is divided into two main components: the manufacturing supply chain and the product supply chain.

What are the benefits of Intel’s supply chain strategy?

Intel’s supply chain strategy has enabled the company to deliver quality products to its customers in an efficient and cost-effective manner. The strategy has also helped Intel to remain competitive in the global technology market, allowing it to maximize its profits and remain a leader in the industry.

What are Intel’s goals for its supply chain?

Intel’s goals for its supply chain include maximizing efficiency and performance, optimizing cost, and providing customers with high-quality products and services. Intel also strives to ensure that its supply chain processes are sustainable and compliant with industry standards.

What type of services do shipping and logistics companies in Dubai provide?

Shipping and logistics companies in Dubai provide a variety of services, including air and sea freight shipping, general warehousing, customs clearance, and supply chain management.