Robotics is playing an increasingly important role in logistics and shipping. Robots can improve efficiency and safety by automating repetitive and physically demanding tasks while reducing costs. For example, robots can be used to load and unload goods from vehicles, sort and assemble products, and pack and unpack boxes. They can also be used to monitor inventory levels and track shipments. In the future, robotics may also be used widely to deliver goods directly to customers. This post will briefly examine each use case that robotics can provide in the logistics and shipping industries.

Table of Contents

Loading and Unloading Cargo

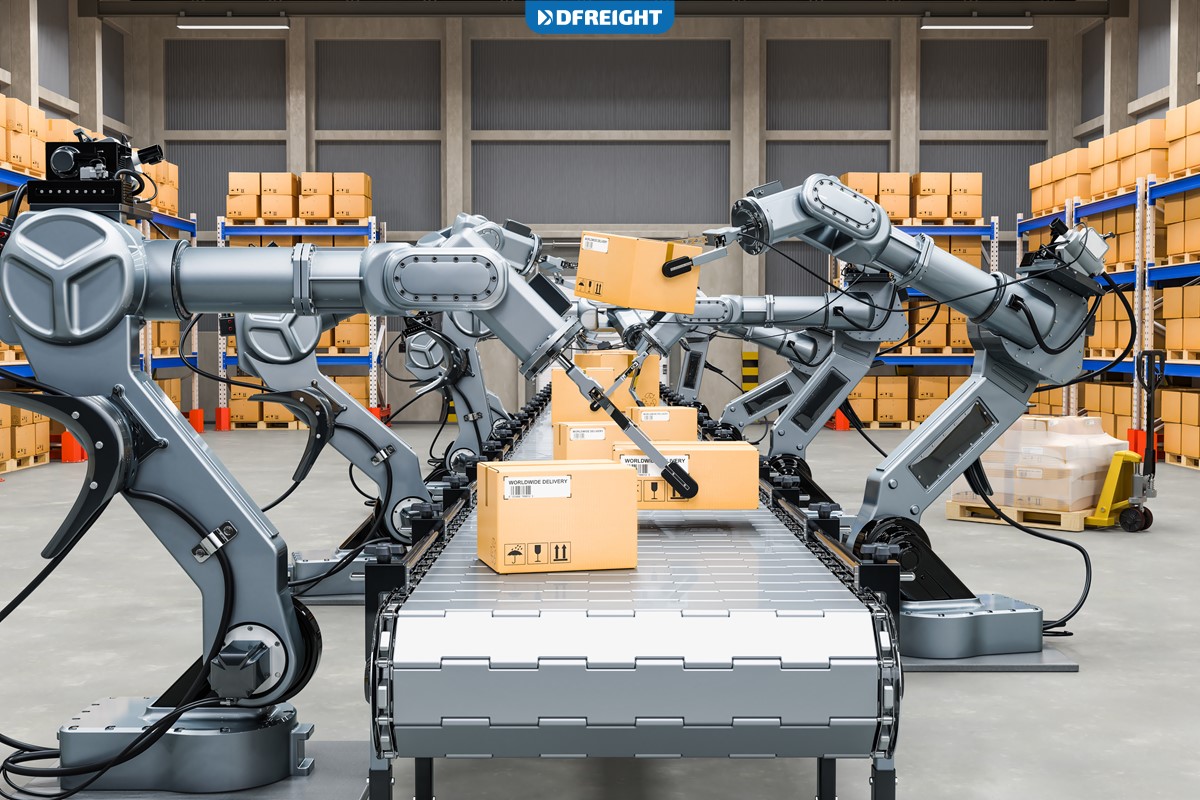

Robotics can be used to load and unload cargo from vehicles in several ways. One way is to use robotics to load the goods onto the vehicle. This can be done by using a robotic arm to pick up the goods and load them onto the vehicle. Another way is to use robotics to unload the goods from the vehicle. This can be done by using a robotic arm to unload the goods from the vehicle and then place them onto a conveyor belt.

Sorting and Assembling Products

Robotics has been used in logistics for many years to help sort and assemble products. In fact, it is one of the most commonly used applications for robotics in business. There are many reasons why robotics is such a good fit for logistics. First of all, robots are very good at repetitive tasks. They can be programmed to sort products by type, size, or other criteria and assemble them in the correct order. This can help improve the assembly line’s efficiency and reduce the number of errors.

Additionally, robots can work around the clock and do not need breaks, which can help increase productivity. Finally, robots can be used in hazardous or difficult environments, such as in warehouses where there is a lot of dust or factories with dangerous goods or chemicals. This means that humans do not need to be put in danger to do these jobs.

Packing and Unpacking Boxes

Robotics has the potential to significantly improve efficiency in the logistics industry, particularly in the packing and unpacking of boxes. By automating these tasks, robots can significantly improve the speed and accuracy with which boxes are packed and unpacked, potentially leading to significant cost savings for logistics companies. In addition, robots can reduce the likelihood of errors and improve safety in the cargo packaging process.

Monitoring Inventory Levels

Robotics can play a vital role in inventory planning and monitoring. By automating the inventory management process, businesses can keep a closer eye on their stock levels and ensure they are never caught short. This can be done by using robots equipped with sensors that can keep track of inventory levels and report back to a central database. This information can then be used to generate reports that can help businesses to make informed decisions about their stock levels.

In addition, robots can also be used to physically count stock levels and report back any discrepancies. This can help businesses keep an accurate and up-to-date inventory record, saving them a lot of time and money in the long run.

Tracking Shipments in Real-Time

Robots are increasingly being used to track shipments in the freight industry. There are several reasons for this. First, robots can quickly and accurately scan and track shipments in real time as they move through the supply chain. This information can then be used to optimize the route and ensure that shipments arrive on time. Second, robots can help to reduce labor costs associated with tracking shipments. By automating the tracking process, companies can save money on labor costs.

Finally, robots can improve the accuracy of tracking data. Robots can provide more accurate and up-to-date information about shipments using sensors and other data-gathering technologies than human workers. This information can be used to improve the shipping process’s efficiency and ensure that shipments arrive at their destination safely and on time.

Automating the Maintenance

Robotics can be used to automate the maintenance of equipment in the logistics and freight industries. This would reduce the downtime of equipment and allow it to be used more efficiently. Robotics can be used to inspect equipment for wear and tear and to identify and diagnose problems. It can also carry out routine maintenance tasks such as lubrication and cleaning. This would reduce the need for human workers to carry out these tasks and allow them to be carried out more frequently and with greater precision.

In addition, robotics can be used to monitor equipment performance and provide operators feedback. This would allow for detecting problems early and implementing corrective measures.

Delivering Goods to Customers

Using drones to deliver goods directly to customers’ doors is becoming increasingly popular. This is because it is a fast and efficient way to get goods to customers without needing them to leave their homes. It also means that customers do not have to go to a store to pick up their items. This is especially useful for people who live in remote areas or who do not have access to a car. Moreover, it can be used to deliver goods to people who cannot leave their homes, such as the elderly or those with disabilities.

Several companies are now using drones to deliver goods. Amazon is one of the most well-known companies to do this. They have been using drones to deliver packages to customers in the United States since 2016. In 2017, they delivered over 10,000 packages to customers using drones. In 2018, they delivered over 20,000 packages. They are also increasing the range of products they can deliver using drones. Walmart is another company that is using drones to deliver goods. They have been working with a company called SkyDrop, (formerly Flirtey) to deliver groceries and other items to customers’ homes. They have completed over 1,000 deliveries since 2016.

There are many benefits to using drone delivery. Firstly, it is a fast and efficient way to get goods to customers. Secondly, customers do not have to leave their homes to pick up their items. Thirdly, it can be used to deliver goods to people who cannot leave their homes. Fourthly, it is an environmentally friendly way to deliver goods, contributing to greener logistics and supply chain sustainability.

Final Words

These are just a few of the many ways robotics is used in the logistics and shipping industries. As technology continues to evolve, we can expect to see even more amazing robotics applications in these industries. As a leading-edge digital freight forwarder, DFreight uses smart shipping technologies to automate logistics and global shipping. By using artificial intelligence, big data, machine learning in logistics, and robotics, DFreight can provide its customers with a superior level of service. From automated pick and pack to load handling and delivery, DFreight is changing how logistics and shipping are done.

FAQs

What are some of the most common uses for robotics in logistics and shipping?

Robotics can be used for a variety of tasks in logistics and shipping, including material handling, order picking, and packaging.

How can robotics help to improve efficiency in the shipping and logistics industry?

Robotics can help to automate and optimize tasks in the shipping and logistics industry, resulting in increased efficiency and productivity. For example, robots can be used to load and unload vehicles, sort and track packages, and assemble orders. By automating these tasks, businesses can reduce costs and improve the accuracy and timeliness of deliveries.

What are some challenges associated with using robotics in logistics and shipping?

Some challenges associated with using robotics in logistics and shipping include the high cost of robots, the need for specialized training for workers, and the risk of robot malfunction.

How do different types of robots contribute to logistics and shipping?

Different types of robots that are used in logistics and shipping include industrial robots, collaborative robots, and mobile robots.

What are the benefits and drawbacks of using robotics in logistics and shipping?

The benefits of using robotics in logistics and shipping include increased efficiency and productivity, reduced labor costs, and improved safety. However, robotics can also lead to increased complexity and the need for specialized training.